Blog

A review of the Wanhao Duplicator I3

Published on

March 8, 2016

This review is actually 3 months old and was originally published on Reddit. I’m now posting it here, so I can further cash in on it.

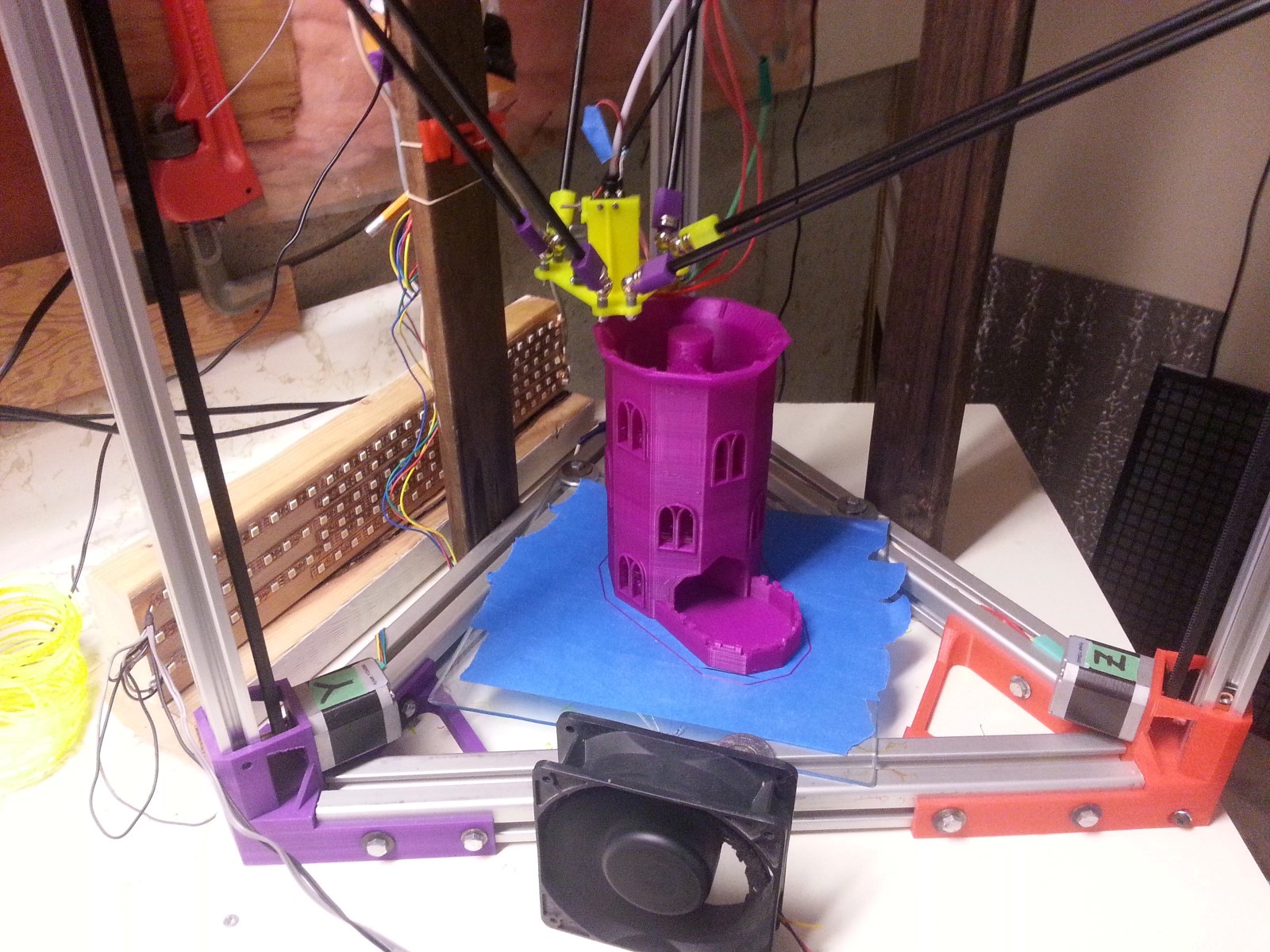

My giant delta, recently decommission due to lack of use and converted into a laser engraver

Wanhao I3 Review

About three years ago I got infected with 3DPrintinitus. I borrowed an Ultimaker, use it to design and print my own giant Delta printer. Since then I helped others build their own printers, and I take care of our MakerSpace printers (Printrbot play and Metal Plus).

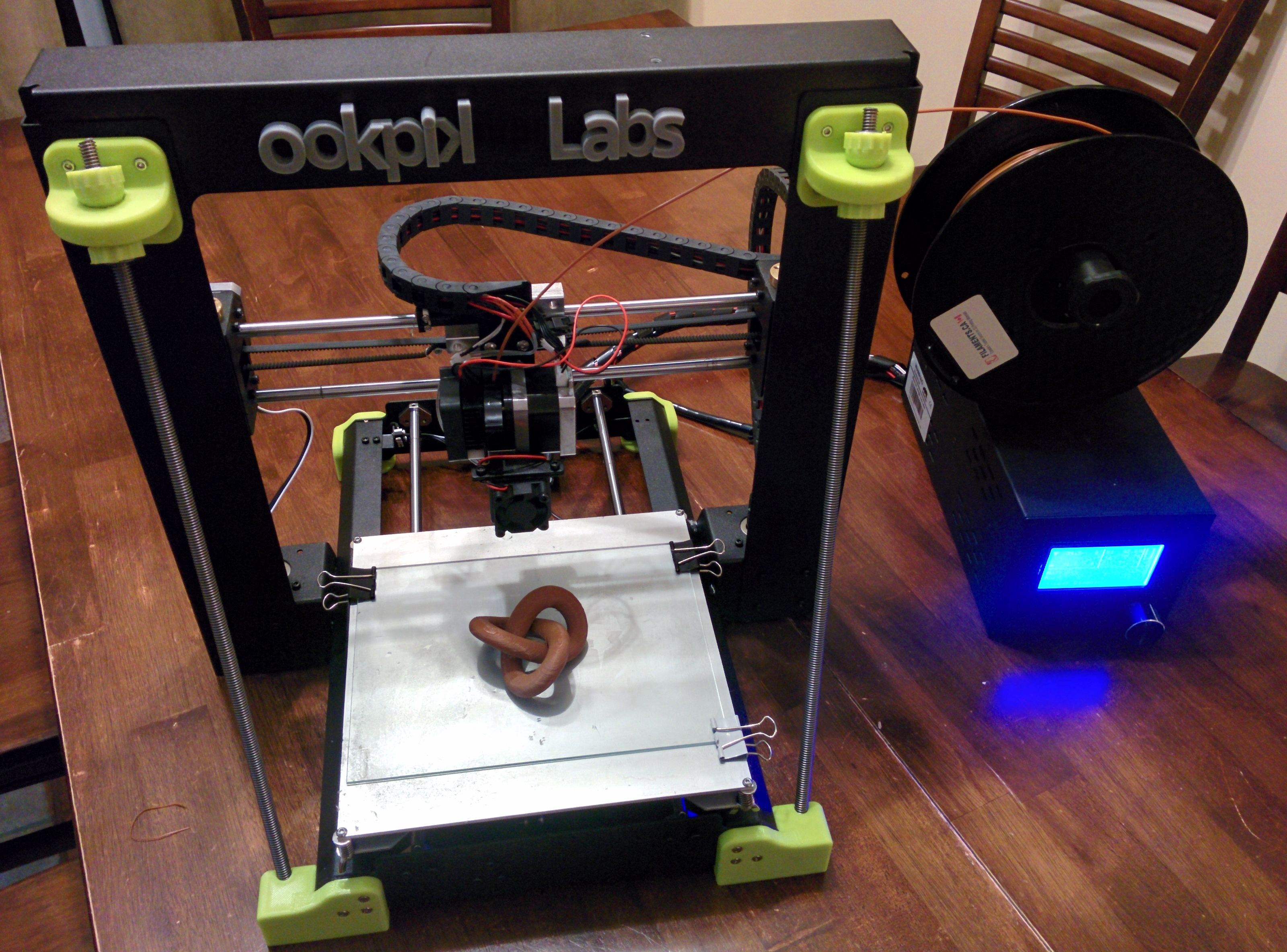

Recently I starting running 3D printing workshops for teens, (check out Ookpik Labs!) so I needed a printer that I could lug around (we do the workshops in different locations). I order a Wanhao Duplicator I3 from their Canadian distributor and got it about 4 days later.

At $400 USD it’s an incredibly capable and sturdy machine, all metal frame with a finish and machining that is surprisingly good.

That is not poo

It has a big LCD, which is a nice touch, but I personally find 3D printer LCD’s to be rather useless. You can navigate the options with the rotary button, but it’s infuriatingly slow and cumbersome. I’ll take a laptop or OctoPrint over that LCD any day.

The heated bed heats up relatively quick and uniform, the aluminum frame that holds it is too thin for my taste and a bit flimsy, but overall it’s decent. It’s highly recommended to add a glass printing surface on top of the aluminum heated bed.

Update: I have since upgraded the bed with a PEI sheet. I can’t recommend this enough. It’s the perfect bed material. Print will stick without warping and detach easily when the bed cools down. Zero maintenance.

The extruder and hotend are a bit underpowered, but again, surprisingly decent.

First prints, almost out of the box

Another thing I love about Wanhao is that they seem to be super attentive to community input, in fact many of the upgrades that I read about before getting the printer have already been included in the version that I got. For example, the Y-axis pulley holder has been beefed up and no longer requires a zip-tie, the Z motors now have dampeners on them, and some other small details. For a printer that’s been on the market for 6 months that is really impressive.

The major mod that I did make was this one: http://www.thingiverse.com/thing:921948

I highly recommend it. It is very well designed and makes the frame a lot more rigid. Especially important if you intend on moving it around.

The major disadvantage for me right now is that the PSU/Controller box is connected by a thick bundle of wires to the printer and is not detachable. This makes it a bit tricky carry it around, since both the PSU and the printer are heavy. I am working on a way to mount and lock the PSU box onto the printer body for ease of transportation.

Another disadvantage is that it’s not a fast printer. 50mm/s is really the top speed you can go before quality goes down, and the extruder starts missing steps. Some people report up to 80mm/s speeds can be achieved with a all-metal hotend. Honestly, I don’t really care if a print takes 4 vs 6 hours. I’m still with the stock hotend.

Conclusion

If you want a really decent, full metal, cheap printer, that will give you great prints if you don’t push it too fast, than get the Wanhao Duplicator I3. So far I love it and I feel that it’s the best value currently on the market, and the only printer I can recommend in the sub-$500 category.

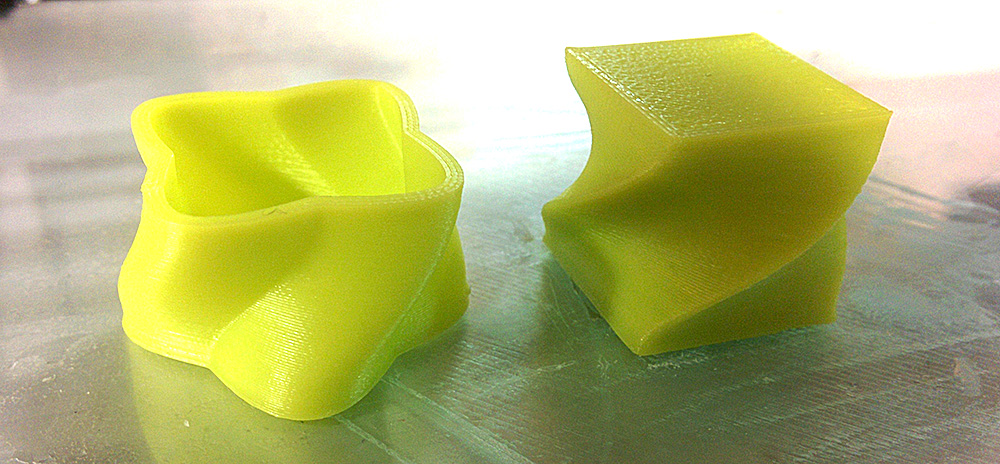

Here is one of my best printers, 11 hours in total, very hard on the retraction. The result is perfect:

The model is my design and is available here:

https://www.youmagine.com/designs/the-shrine